Get 15% Off Direnza – Use Code: GRID15

- Exhausts

- Cooling

- Lowering Springs

- Engine & Drivetrain

- Air Induction

- Wheel Spacers

- MVT

Multi-Vane Technology

- Merchandise

Mini Cooper S F55 F56 F57 2013+ MVT Front Mount Intercooler

- QUICK DELIVERY

- WARRANTY INCLUDED

- UK STOCKED PRODUCT

- +23.6hp / +21nm

- 86% Larger than Stock

- -22.5°c Intake Temps

- Black coating improves heat dissipation properties

- Designed using state of the art 3D CAD and CFD modelling

- Direct replacement for the original core

- Supplied with spacers, allow the thicker core to be installed

- TIG welded for maximum strength and durability

MVT technology designed by Direnza offers greater intercooler efficiency in comparison to other aftermarket alternatives. This is achieved through the use of carefully placed vanes in the end tank which evenly distribute air across the entire core. Ensuring the full surface area of the intercooler core is optimised to cool your charged air, resulting in more power.

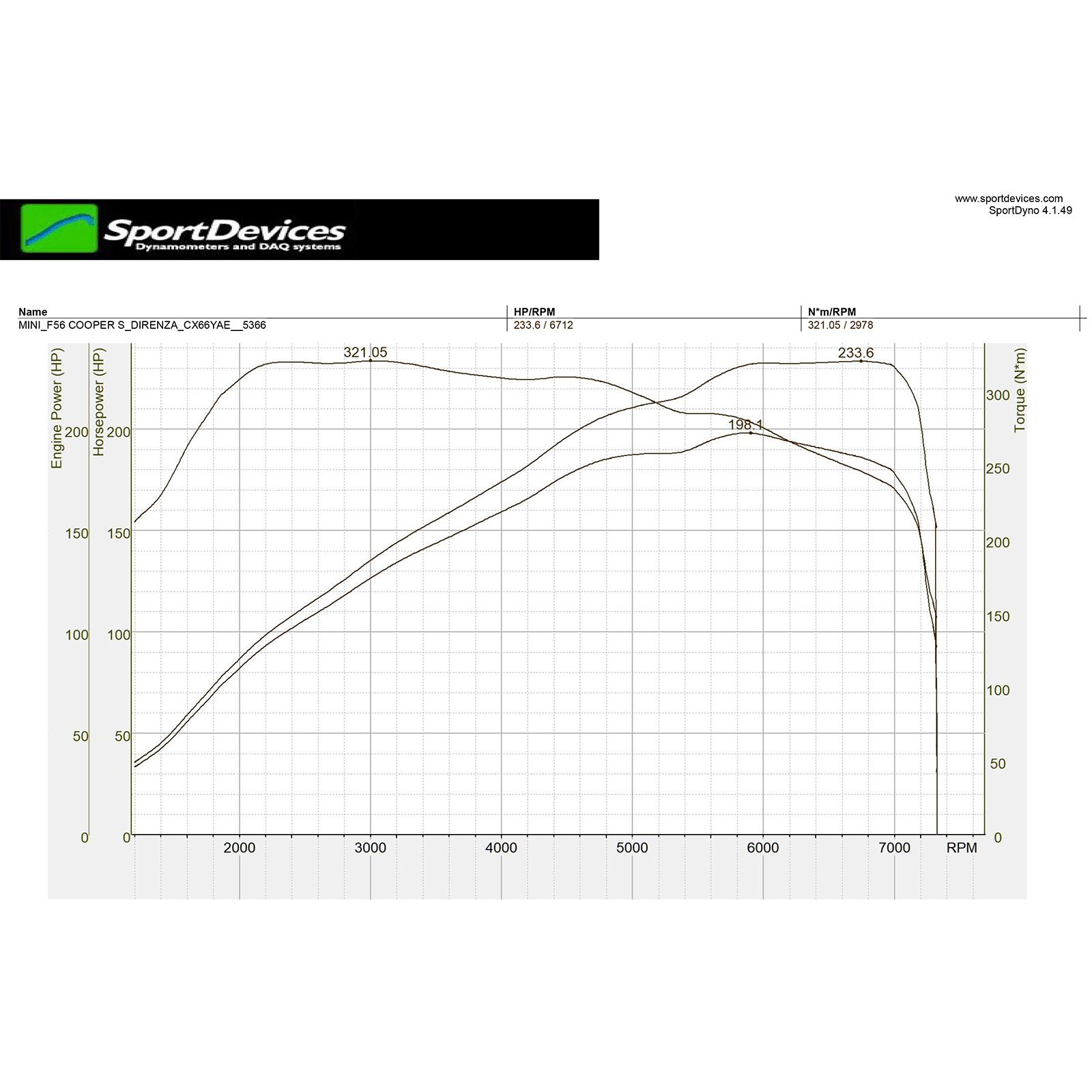

Test car: Mini Cooper F56 S Works 210 210hp / 300nm

Put through its paces on a state-of-the-art Maha MSR 500 Dyno, our Multi Vane Technology Intercooler for the F56 Cooper S yielded some highly impressive results.

After installing our revolutionary MVT Intercooler, engine performance improved significantly. With the F56 now producing 233.6hp & 321nm of torque, that’s an increase of +23.6hp & 21nm of torque without any additional tuning.

What’s more impressive is the cooling power of MVT. Using sophisticated data logging software, stock intake temperatures where measured at 39°c at the start of the dyno run. This increased to 45°c by the end of the same run. However, with MVT installed, intake temperatures actually reduced from 30.75°c at the start of the run down to 22.5°c! That’s a drop of 22.5°c at peak power. Thus, providing huge tuning potential and greater reliability when combined with a remap & supporting modifications. The perfect addition to any track or modified road car!

Stock dimensions: 585mm x 150mm x 95mm

Stock volume: 8,300cm3

MVT dimensions: 581mm x 234mm/stepped x 155mm

MVT Volume: 15,540cm3

Fitment

Mini Cooper S F56 2.0T 2013+ models

In stock

£399.99

In stock

Buy 2 Products

Order any two products to get 5% off your whole order

Buy 3 Products

Order any three products to get 10% off your whole order

Buy 4 or More Products

Order four or more products to get 15% off your whole order

*DOES NOT INCLUDE MERCHANDISE

- Specifications

- Description

- Delivery & Returns

- What is MVT?

- Manufacturer Information

Additional information

| Weight | 10 kg |

|---|---|

| Overall Length | 800mm |

| Overall Height | 210mm |

| Overall Width | 235mm |

| Core Length | 570mm |

| Core Height | 145mm |

| Core Width | 235mm |

| Inlet Size | 56mm |

| Outlet Size | 56mm |

- +23.6hp / +21nm

- 86% Larger than Stock

- -22.5°c Intake Temps

- Black coating improves heat dissipation properties

- Designed using state of the art 3D CAD and CFD modelling

- Direct replacement for the original core

- Supplied with spacers, allow the thicker core to be installed

- TIG welded for maximum strength and durability

At Direnza we offer you our best prices but to do this all our website prices only include delivery to the UK mainland. If your delivery address is outside the UK mainland please be aware there may be additional shipping charges. If this is the case; we will contact you before any payment is processed.

We aim to dispatch all orders within 3 working days. If there is going to be a delay with dispatching your order we will contact you to advise you of this.

We buy all our products in bulk in order to keep prices low and ensure we always have what you’re looking for in stock. However there may be occasions we are out of stock of a product you have ordered. If this is the case we will notify you as soon as possible and refund any payments made for the product in question.

Any goods found to be faulty within 12 months of purchase will be repaired and where this is not possible, replaced. Please be aware that Direnza will not be held responsible for any labour costs incurred for fitting of our products whether faulty or not.

Please note all items must be installed by a qualified mechanic at a registered garage. Failure to do this will invalidate any warranty and returns policy. For information on warranty offered on your purchase, please either contact us by email at sales@direnza.co.uk or phone us on +44 (0) 844 448 2002.

Along with this, if you no longer require any items within your order, you have 14 days after delivery to cancel your order and return the goods back to us. All of our products are made with the highest quality materials and checked prior to dispatching.

If you have any issues with your product, you have the right to contact us and for us to get the issue resolved, in accordance of the Consumer Rights Act 2015.

MULTI VANE TECHNOLOGY

MVT stands for Multi Vane Technology. This revolutionary design enhances the efficiency of an intercooler by using vanes in the end tank to redirect air across a much larger area of an intercooler core. This leads to reduced intake temperatures and increased engine performance. But exactly how do we design our award-winning MVT intercoolers?

3D Scanning

We begin by scanning all aspects of the OEM intercooler and the front of the car. These scans allow us to accurately measure how much space is available for a new intercooler. The scanner builds three-dimensional computer visuals that can be rotated and viewed from any angle.

Computer-Aided Design (CAD)

Once we have completed the scans, we convert the files into a format compatible with our state-of-the-art CAD software. The scans are used as a base to build our own intercooler models. We do this to ensure accurate fitment, by matching OEM end tank positions and mounting points. End tanks are individually designed to optimize size, flow and efficiency. The resulting model is overlaid onto the 3D scans we gathered earlier to double-check for clearance around the front of the car.

Computational Fluid Dynamics (CFD)

With the model built, we use CFD analysis to simulate airflow through the intercooler. We do this to check an intercooler’s efficiency before we start designing our vanes (MVT). With the aid of CFD simulations, we can design our vanes to maximize cooling efficiency, utilizing as much of the core’s surface area as possible. We are also able to see how the smallest alterations can affect this. We repeat this process until each design meets our high standards.

CFD analysis shows us the disadvantages of commonly used angled end tanks. The sharp angles result in the flow of air being restricted. This would ultimately result in an increased pressure drop across the intercooler and the turbo would be required to work harder to produce boost. Direnza engineers instead use cast end tanks, which offer exceptional airflow characteristics. This is enhanced further with MVT, which distributes air evenly across the core, lowering intake temperatures and reducing pressure drop.

3D Printing & Test Fitting

After we have completed our CAD work, the model is printed in full scale on one of our 3D printers. An intercooler print generally takes a few days to complete. We can use this to test fitment on the car, noting down any adjustments required. Once happy with the design, fitment and performance simulations a pre-production example can be manufactured and go through another stage of testing. This stage of testing will include fitment and real-world performance.

Manufacturer

Company name

Jap Parts Europe LTD

Address

Units 2 – 4 Southern Industrial Estate, Southern Street, Manchester, Lancashire, M28 3QN, UK

sales@direnza.co.uk

Phone

08445561266

EU responsible person

Company name

jpe-ltd.eu

Address

Davisstraat 10, Maasvlakte, Rotterdam, 3199 MA, NL

info@jpe-ltd.eu

Phone

+44 (0) 844 448 2002

Related products

-

Vauxhall Opel Astra G MK4 | Zafira MK1 Z20LET 2.0 Turbo GSI 99-05 – Aluminium Performance Black Radiator

£239.99 View Item -

VW Golf MK3 2.0 8V 16V GTI 91-99 – Aluminium Performance Radiator

£239.99 View Item -

BMW 5 E39 / 7 Series E38 – Aluminium Performance Radiator

£199.99 View Item -

Fiat Coupe 2.0 20V Turbo 96-00 – Aluminium Performance Black Radiator

£234.99 View Item